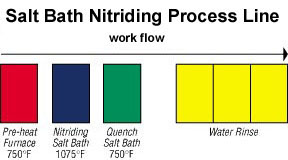

Salt Bath Nitriding

Salt Bath Basics

TS - Houston Unlimited LLC, Inc. offers a salt bath nitriding process, also referred to as liquid salt bath ferritic nitrocarburizing. This process is a surface treatment for most ferrous metal components and is designed to improve certain engineering properties to enhance wear resistance, lubricity, fatigue strength and corrosion resistance (except for stainless steel). This nitriding process will also lower the coefficient of friction and possibly reduce the material cost of components i.e., low alloys versus high alloys.

Salt Bath Processes

Salt bath nitriding is a thermochemical process in which nitrogen and carbon are diffused simultaneously into the surface of the material. The high concentration of nitrogen chemically combines with iron and other nitride forming elements to produce an outer layer of epsilon iron nitride ( Fe3N ) which is thin, hard and ductile.

This layer is also known as the compound zone which has increased surface hardness to enhance anti-galling characteristics and lowers the coefficient of friction. This compound zone also functions as a solid film lubricant by providing a non-metallic interface between mating surfaces. Nitrogen of lower concentration continues to diffuse below the compound zone and forms a solid solution with the base metal iron. This zone is referred to as the diffusion zone and is noted for its improvement in fatigue strength.